Horizontal Batch Feeding Carbonization Furnace is a specialized furnace designed for batch processing of biomass and organic materials to produce high-quality charcoal. It features a horizontal structure for efficient loading and unloading, making it ideal for materials like wood, coconut shells, and agricultural residues.

Raw Materials

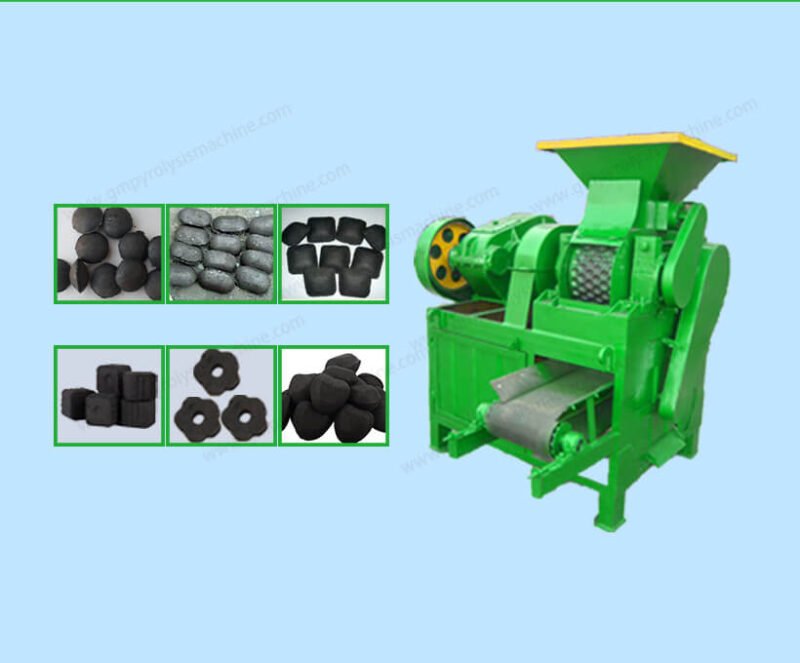

The batch carbonization furnace processes a wide variety of raw materials, almost all the biomass can be made into charcoal, including but not limited to wood chips, corn cobs, coconut shell, branches, palm kernel shells , sawdust, bamboo, coconut shells, rice husks, and other agricultural waste. These materials are fed into the furnace in batches, where they undergo carbonization under controlled temperatures to produce charcoal. Making different shapes of carbon through charcoal briquette making machine.

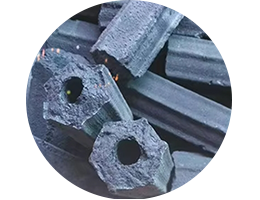

Final Products

The final product of the batch carbonization furnace is high-quality charcoal. This charcoal is widely used in various industries, including fuel production, metallurgy, and as an ingredient for making activated carbon. The product’s consistent quality makes it suitable for both domestic and commercial use, offering an eco-friendly alternative to traditional charcoal.

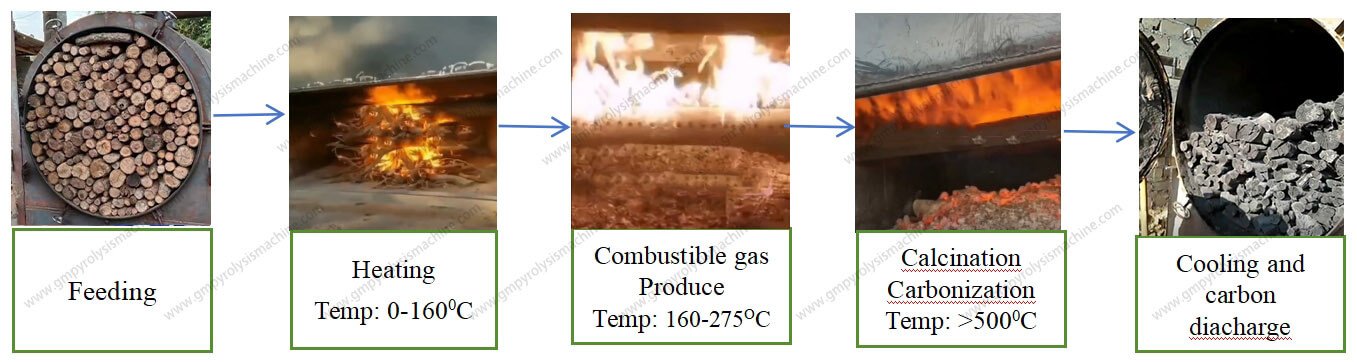

Process Flow

Guanma Machinery Bacth Carbonization Furnace Process Flow

1. Feeding: put organic materials (such as wood, straw, plant residues, etc.) into the carbonization chamber.

2. Heating: provide sufficient heat through a heating system to allow the materials to undergo carbonization reactions in a relatively enclosed environment.

3. Carbonization: During the carbonization process, the material undergoes stages such as dry distillation and carbonization, ultimately transforming into biochar or charcoal with high carbon content.

Technical Parameters

| Model | BCF-500 | BCF-1000 | BCF-2000 | BCF-3000 |

| Output Capacity | 500kg/day | 1t/day | 2t/2day | 3t/3day |

| Size | 1800*1700*2200mm | 3300*1600*2400mm | 4300*1800*2400mm | 4800*2300*2600mm |

| Workflow | Batch | Batch | Batch | Batch |

| Material | Q245R | Q245R | Q245R | Q245R |

| Weight | About 1000kg | About 1800kg | About 3000kg | About 4500kg |

| Heating Materials | Natural gas, biomass, etc. | |||

| If you have other requirement and want to know more details, please contact us.(The data in this table are for reference only) | ||||

To meet different requirements, Guanma Machinery provides three types of charcoal making machines: continuous carbonization pyrolysis machine, mobile biochar making machine and batch type carbonization furnaces, with outputs ranging from 100kg to 50000kg per hour.

Advantages

Advantages of Guanma Machinery's Batch Charcoal Making Machine:

Efficient Carbonization: The Batch Carbonization Furnace ensures efficient conversion of biomass into charcoal.

Low Maintenance: With simple and durable construction, the batch type furnace requires minimal maintenance, making it cost-effective for long-term use.

Versatile Raw Material Processing: This machine can process various types of biomass, including wood, agricultural waste, and even rubber, offering high flexibility in raw material sourcing.

High-Quality Charcoal: The controlled environment inside the furnace ensures the production of high-quality, uniform charcoal suitable for various industrial applications.

Why Choose Guanma Machinery Batch Carbonization Furnace?

Guanma Machinery batch carbonization furnace manufacturers, we offer a high-quality, reliable machine that is built to meet the demands of modern charcoal production. Our batch type charcoal making machines are engineered with the latest technology to ensure consistent performance, energy efficiency, and long service life.

If you’re looking for a high-performance, affordable batch type furnace, our Batch Type Carbonization Furnace is the ideal solution.

Customer Visiting

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)