Guanma Machinery offers a batch pyrolysis plant for sale, providing businesses with the opportunity to invest in sustainable waste tire recycling technology. Whether you’re looking to start a new recycling business or expand an existing operation, our batch pyrolysis plants offer a proven solution for waste tire management.

Raw Materials

The batch tire plastic pyrolysis plant processes a wide variety of raw materials, including but not limited to:

Waste Tires: mechanical tires, bicycle tires, motorcycle tires and other tires.

Waste Rubber: waste cable, rubber soles, rubber gloves, etc.

Plastic: waste acrylic (PMMA), PE, PP.

Sludge Oil: sewage sludge, oil mud, oil sludge, etc.

NOTE: Different raw materials have different oil yields, Please contact Guanma Machinery for details.

Final Products

Final product of waste tire pyrolysis machine: tyre oil, carbon black, scrap steel wire, oil gas.

Our batch tire plastic pyrolysis plant is designed to process both waste tires and plastics, making it a versatile addition to any recycling facility. This machine utilizes pyrolysis technology to break down rubber and plastic waste into useful products like fuel oil and carbon black.

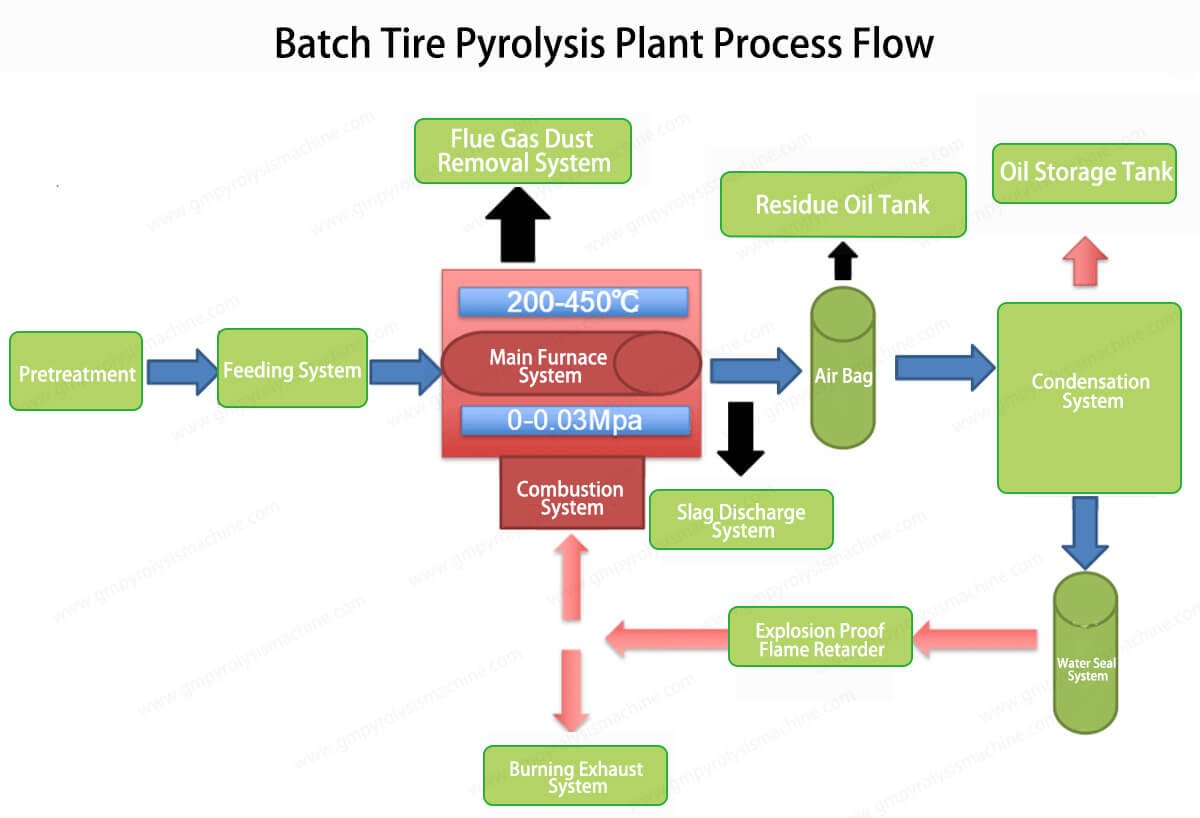

Process Flow

Guanma Machinery batch waste tire pyrolysis plant Process Flow

The batch waste tire pyrolysis plant processes are designed for simplicity and effectiveness. The process begins by feeding waste tires into the reactor. Once the reactor is sealed, heat is applied to initiate the pyrolysis process. Over time, the tires break down into fuel oil, carbon black, and gas. The gas is often used as a fuel to heat the reactor, further enhancing the plant’s energy efficiency. The oil can be used as a substitute for diesel or other fuel products, while the carbon black can be processed into a variety of commercial products.

Oil Yield

| Oil Yield from Different Raw Materials | |

|---|---|

| Raw Materials | Oil Yield |

| General Rubber | |

| Big car tires, truck tires, OTR tires | 45-52% |

| Small car tires, bicycle tires | 35-40% |

| Rubber cable sheath, rubber soles | 35% |

| All kinds of rubber sheets or carpets | 30% |

| Unclassified rubbers | 35% |

| General Plastic | |

| Pure PE/PP/PS plastics | 90-95% |

| Pure plastic cable sheath | 80% |

| Pure white plastic sheets | 70% |

| Pure plastic bags | 50% |

| ABS | 40% |

| Instant noodles packing bags | 40% |

| Plastic household garbage | 30-50% |

| Plastic logo | 20% |

Technical Parameters

| Batch Tire Pyrolysis Equipment Technical Parameters | |||||

| Model | TPP-15 | TPP-20 | TPP-30 | TPP-40 | TPP-50 |

| Capacity | 12-15T/D | 16-20T/D | 21-30T/D | 31-40T/D | 41-50T/D |

| Raw Materials | Waste Plastic, Waste Tyre, Rubber, Oil Sludge | ||||

| Final Product | Tyre oil, Carbon Black, Scrap Steel Wire, Oil Gas, Muck | ||||

| Heating Materials | Coal, Fuel Oil, Natural Gas, LPG, etc. | ||||

| Working Method | Fully Continuous | ||||

| Cooling Method | Water Cooling | ||||

| Operating Pressure | Negative Pressure | ||||

| If you have other requirements and want to know more details, please contact us. (The data in this table are for reference only) | |||||

To meet different needs, Guanma Machinery provides three types of waste tire pyrolysis equipment: fully continuous tire pyrolysis machine, semi-continuous tire pyrolysis equipment and batch tire pyrolysis plant. Please contact us for details.

Advantages

Guanma Machinery is a trusted batch tyre pyrolysis machine manufacturer, known for producing high-performance pyrolysis systems. Our batch pyrolysis plants come with several key advantages:

Energy-efficient: The design of the plant allows the gases produced during the pyrolysis process to be reused for heating, reducing energy costs.

Environmentally friendly: The process minimizes harmful emissions and pollutants, ensuring compliance with environmental regulations.

High product yield: The plant maximizes the conversion of waste tires into valuable products like oil and carbon black.

Durability and safety: Built with high-quality materials, our batch pyrolysis machines offer long-lasting performance and safety.

Why Choose Guanma Machinery Batch Tire Pyrolysis Plant Manufacturers?

Investing in a batch tire pyrolysis plant from Guanma Machinery ensures that you are adopting an efficient, sustainable, and profitable approach to tire and plastic waste management. Contact us today to learn more about how our solutions can fit your recycling needs.

Customer Visiting

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)