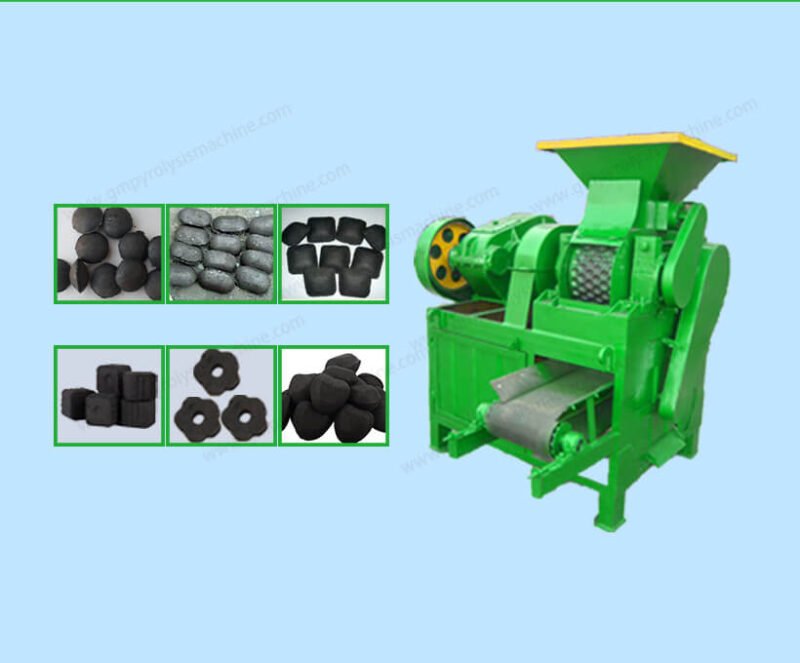

This carbon black briquette mmachine is widely used in coal, metallurgy, chemical industry and other industries. The final product can be made into egg-shaped, oval, round, square, cylindrical, strip, cake, etc. The final product size range is 18mm-80mm and can be customized according to customer needs.

Raw Materials

Carbon Black

Coal

Aluminum Dross

Gypsum Powder

Iron Ore Fines

Iron Powder

Coke

Burnt Lime

Carbon black briquette machine mainly uses carbon black powder, which is a byproduct of pyrolysis of waste tires or other materials. The briquette machine can press materials such as mineral powder, metal powder, coal powder, coke powder into balls, and can also use other materials such as charcoal or biomass residues, making the machine versatile.

Final Products

Heart Shape

Coal Briquette

Flower Shape

Cylindrical Shape

The final product of carbon black briquette machine, charcoal or briquettes can be made into various shapes through molds, such as oval, pillow, round, egg, spherical, cylindrical and square. We can also customize the shapes for customers.

Process Flow

The process of making carbon black briquettes begins with feeding raw materials such as carbon black or charcoal powder into a briquette machine. The machine then compresses the powder into compact briquettes under high pressure. The key steps involved in the process are as follows:

1. Raw material preparation: Collecting, cleaning and mixing (if necessary) carbon black powder to ensure uniformity and consistency.

2. Compression: The prepared material is fed into the briquette machine and compressed under high pressure to form the desired shape.

3. Cooling: Cooling the newly formed briquettes ensures that they retain their shape and strength.

4. Storage and Packaging: After cooling, the briquettes are stored or packaged for distribution.

The machine offers an efficient and environmentally friendly process, and the entire process is automated, ensuring high yields with minimal labor. The charcoal briquette machine operates efficiently with short start-up time and low downtime.

Technical Parameters

| Model | CBM-3600 | CBM-450 | CBM-650 | CBM-850 | CBM-1000 |

|---|---|---|---|---|---|

| Capacity | 1-3 ton/h | 4-5 ton/h | 5-9 ton/h | 10-20 ton/h | 20-30 ton/h |

| Power | 6 kW | 8 kW | 20 kW | 50 kW | 90 kW |

| Type of Pressure | Mechanical | Mechanical Hydraulic | |||

| Material of Roller | 65Mn 9Cr2 | 65Mn 9Cr2 | |||

| Roll Size (mm) | 300*240 | 450*280 | 550*380 | 750*500 | 1000*500 |

| Weight (kg) | 1200 | 3800 | 5800 | 9800 | 22000 |

| Working voltage can be customized, and if you have other requirements or want to know more details, please contact us. (The data in this table is for reference only) | |||||

The production capacity of charcoal briquette production line varies according to the model and the specific requirements of the customers. It usually includes hopper, screw feeder, agitator, conveyor, conveyor belt. Charcoal briquette machines are available in different sizes and configurations and can be customized according to production needs.

Advantages

Advantages of Guanma Machinery's Carbon Black Briquette Machine:

The Carbon Black Briquette Machine comes with several advantages that make it an excellent choice for businesses looking to maximize efficiency and reduce operational costs:

High Efficiency: The machine operates at a high capacity, converting large quantities of carbon black powder into compact briquettes quickly.

Customization: Adjustable settings for briquette size and shape allow for customization, depending on specific requirements or market needs.

Cost-Effective: The machine reduces the need for disposing of carbon black waste, saving businesses money while providing a marketable product.

Environmental Benefits: By transforming carbon black waste into useful briquettes, this machine contributes to reducing environmental pollution.

Customer Visiting

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)