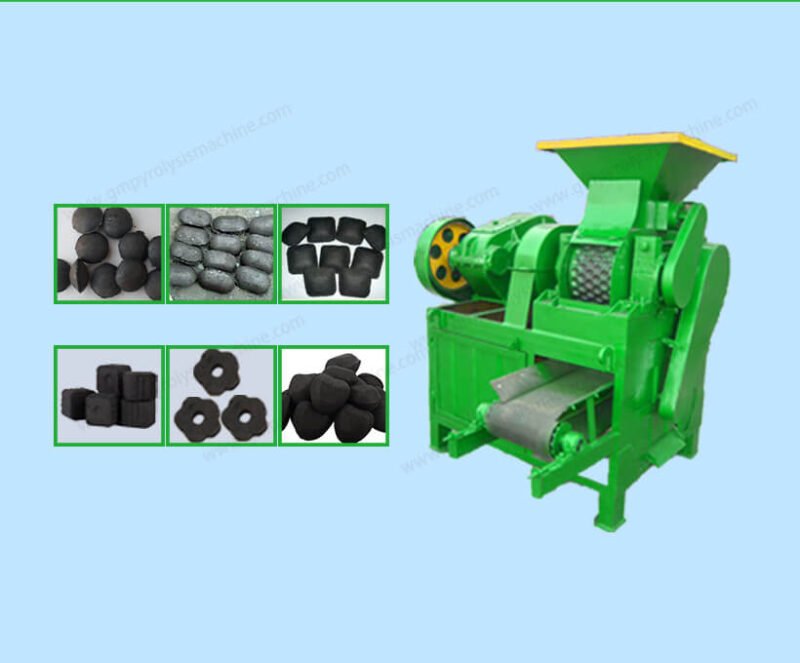

The charcoal briquette making machine manufacturer uses the principle of spiral extrusion to compress coal powder and charcoal powder into the desired shape with a certain strength. charcoal briquette extruder machine is perfect for producing uniform, durable briquettes for industrial and household applications.

Raw Materials

The charcoal briquette making machine is capable of processing a wide range of raw materials, including: sawdust, coconut shell, bamboo, crop waste, rice husks, crop stalks, wheat brans, groundnut shells, paddy straw, coffee shells, palm shells, sunflower stalk, cotton stalks and so on. These raw materials are compressed into high-quality briquettes, ideal for fuel or further carbonization.

Final Products

Plum Blossom Charcoal

BBQ Charcoal

Charcoal Granules

Charcoal Pellets

The final product is compact, uniform charcoal briquettes with a smooth surface and high density. These briquettes are widely used in: Barbecue and grilling, Industrial heating, Home heating and cooking.

Custom shapes and sizes are achievable based on the specific needs of customers.

Process Flow

The charcoal briquette making machine process mainly includes the following steps:

1. Crushing and mixing machine: Raw materials are crushed to ensure uniformity.

2. Wheel mill: Mixing the raw material powder with the appropriate binder.

3. Charcoal briquette extrusion machine: Different charcoal briquettes are formed by different types of charcoal briquette making machines.

4. Drying Equipment: Moisture is removed to maintain the desired water content for briquetting.

Technical Parameters

| Charcoal Briquette Making Machine Technical Parameters | ||||

| Model | Capacity | Power | Weight | Size(mm) |

| CRM-140 | 800-1000/h | 15kw | 360kg | 1160*800*600 |

| CRM-160 | 1.5ton/h | 22kw | 620kg | 2120*1260*1080 |

| CRM-180 | 2ton/h | 30kw | 1260kg | 2320*1600*1130 |

| If you have other requirements and want to know more details, please contact us. (The data in this table are for reference only) | ||||

Coal rod machine manufacturers sell various types of coal rod machines, and the processing capacity can be customized according to needs.

Advantages

Advantages of Guanma Machinery's Charcoal Briquette Making Machine:

The charcoal briquette making machine can convert raw materials into charcoal shapes and sizes that meet customer requirements. The advantages of the charcoal briquette extruder machine are mainly as follows:

Cost-Effective: The competitive charcoal making machine price makes it affordable for small and medium-scale operations.

Energy Efficient: Designed with low power consumption for optimized performance.

Durable Construction: High-quality materials ensure long-lasting operation.

Easy Operation: User-friendly interface simplifies the briquetting process.

Customizable Output: Supports various shapes and sizes based on requirements.

Why choose Guanma Machinery Charcoal Briquetting Machine?

Guanma Machinery is a charcoal briquetting machine manufacturer with a full range of models, fully automatic charcoal machines for sale at low prices and high quality!

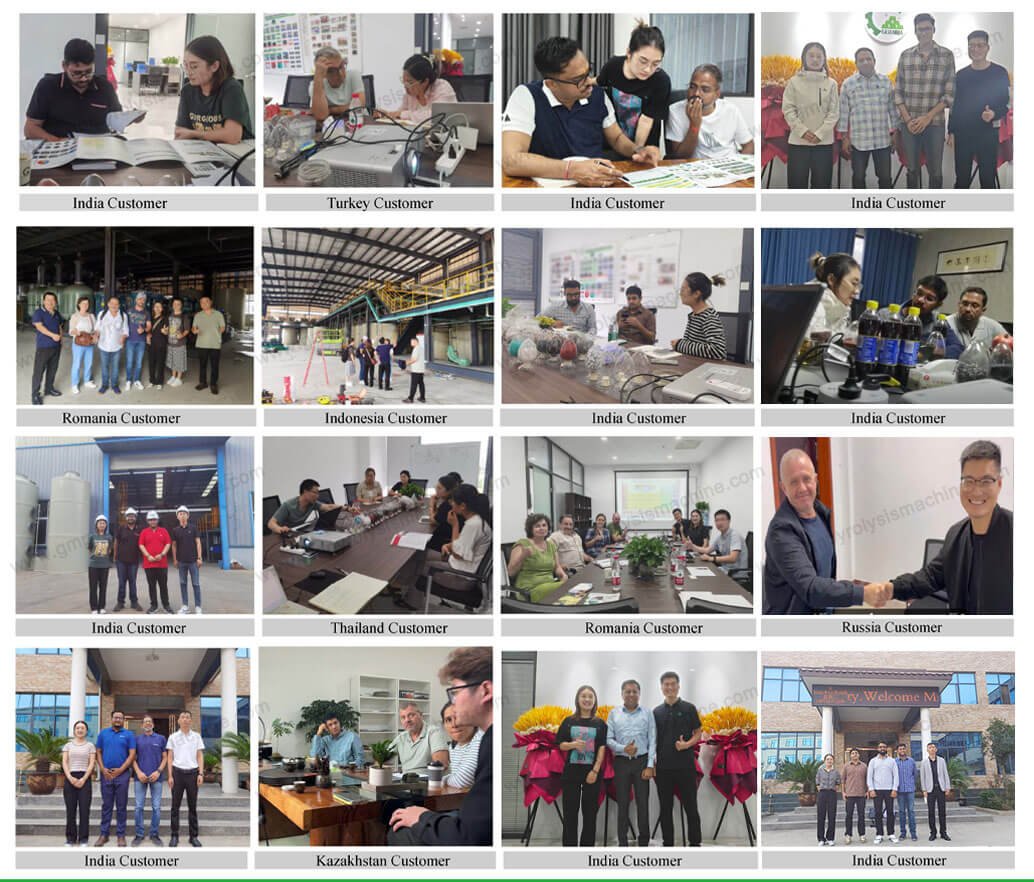

Customer Visiting

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)