Raw Materials

Biomass Continuous Carbonization Pyrolysis Machine can process: coconut shells, rice husks, sawdust, straw, pistachio shells, palm shells, bamboo, wood chips, bagasse and other raw materials.

Waste Lithium Batteries

Scrap Aluminum Capacitor

Waste PCB Board

Scrap Solar Panel

Solid waste carbonization machine can process: waste batteries, solar photovoltaic panels, aluminum-plastic panels, aluminum capacitors, circuit boards, cans and other raw materials.

Industrial Sludge

Dyeing Sludge

Anode Sludge

Sewage sludge carbonization machine can process: including civil sludge, urban sludge, industrial sludge and other raw materials.

Final Products

Charcoal

Tar

Wood Viniger

Combustible Gas

Continuous carbonization pyrolysis machine final products: biochar, wood vinegar, tar, combustible gas.

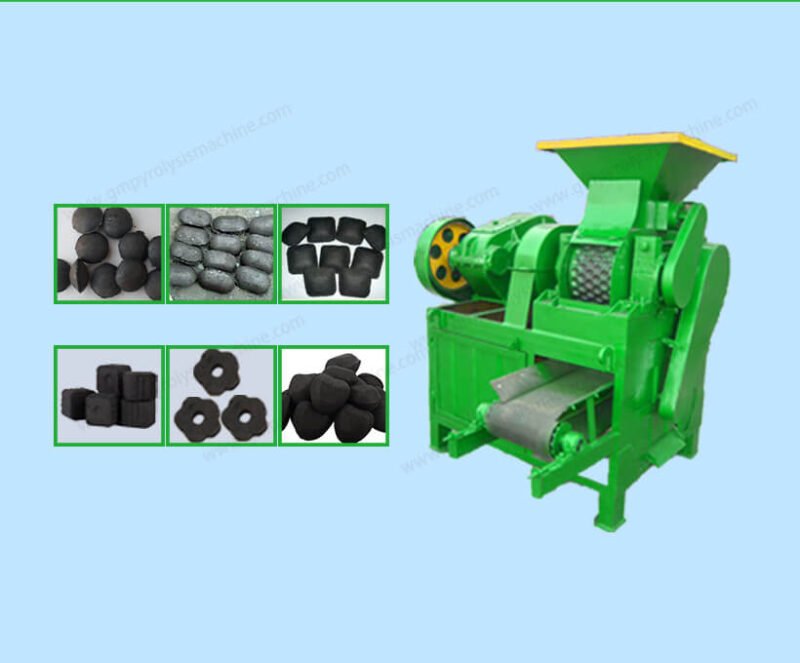

Charcoal Further Process(Charcoal forming machine)

Through the charcoal further processing machine, you can get charcoal sticks, charcoal briquettes, charcoal balls, hookah charcoal, activated charcoal, BBQ charcoal, etc.

Detection of Common Finished Biochar

| Testing Item | Units | Rice Husk (Hunan City) | Rice Husk (Tianjin City) | Coffee Shell | Pecan Shell | Saw Dust | Coconut Shell | Bamboo | Corn Stalk | Sunflower Stem | Reed Cane |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Full Water(Mt) | % | 6.09 | 5.12 | 11.78 | 1.71 | 6.84 | 9.1 | 6.98 | 0.78 | 0.8 | 0.62 |

| Analytical Water(Mad) | % | 3.58 | 2.59 | 1.21 | 1.7 | 4.51 | 4.19 | 1.74 | 0.15 | 0.2 | 0.66 |

| Ash(Ad) | % | 39.08 | 49.21 | 2.75 | 4.42 | 5.78 | 0.18 | 16.62 | 50.96 | 18.92 | 89.16 |

| Volatile Matter(Vd) | % | 19.12 | 13.37 | 30.96 | 7.03 | 20.8 | 6.95 | 18.2 | 10.96 | 11.02 | 5.5 |

| Fixed Carbon(Fcad) | % | 38.22 | 34.83 | 65.08 | 86.84 | 68.91 | 88.68 | 63.44 | 37.99 | 69.9 | 4.68 |

| Sulfur Content(St.d) | % | 0.12 | 0.17 | 0.02 | 0.02 | 0.08 | 0.09 | 0.02 | 0.02 | 0.04 | 0.77 |

| High Calorific Value | Kcal/kg | 3860 | 3396 | 7050 | 7484 | 6454 | 7277 | 5679 | 706 | ||

| Low Calorific Value | Kcal/kg | 3559 | 3127 | 6053 | 7332 | 6088 | 6724 | 5171 | 566 |

Process Flow

1. Material Conveyance: Materials are typically fed into the continuous carbonization furnace in granular or block form. Raw material size need to less than 2cm.

2. Preheating and Drying(Alternation): The preheating temperature is usually about 150 ° C, and the moisture is controlled below 15%.

3. High-Temperature Carbonization: After entering the carbonization furnace, the materials pass through a series of heat treatment zones.

4.Collection of Carbonized Products: These products typically include charcoal and some residual ash.

5.Molding (optional according to the use of toner finished products) : According to different uses of toner can be made into corresponding rod, ball finished products. Such as barbecue carbon, Hookah carbon, etc.

6.Waste Gas Treatment: Common waste gas treatment methods include spray towers, waste gas incineration, or other gas treatment systems.

Technical Parameters

To meet different requirements, Guanma Machinery provides three types of charcoal making machines: skid monted, batch and fully continuous, with outputs ranging from 100kg to 50000kg per hour. We list the common carbonization machine models.

| Model | CF-800 | CF-1000 | CF-1200 | CF-1500-I | CF-1500-II | CF-1800-I | CF-1800-II |

|---|---|---|---|---|---|---|---|

| Capacity | 600kg/h | 800kg/h | 1000kg/h | 1200kg/h | 1300-1500kg/h | 1500-1800kg/h | 2000-2200kg/h |

| Land Requirement | 150m² | 240m² | 350m² | 400m² | 400m² | 500m² | 500m² |

| Total Power | 11.2kw | 11.2kw | 16.5kw | 21.5kw | 24.5kw | 33.5kw | 41kw |

| Weight | 13t | 16t | 21t | 26t | 30t | 36t | 40t |

| Raw Materials | Biomass: coconut shell, rice husk, sawdust, straw, pistachio shell, bamboo, charcoal, walnut shell, pistachio shell, peanut shell, sugar cane… Solid Waste: waste lithium battery, aluminum capacitor, can paint removal, solar panel, circuit board… Sludge: industrial sludge, dyeing sludge, anode sludge, etc. | ||||||

| Raw Materials Requirement | Size≤2cm, Water Content<15%, Forced Feeding | ||||||

| Heating Source | Diesel/LPG/LNG/Heavy Oil/Biomass Fuel/Electricity | ||||||

| Working Pressure | Micro Negative Pressure | ||||||

| Reactor Material | Q245R+SS304+SS316+SS310S | ||||||

| Control System | PLC Control | ||||||

Analysis of Profit

| Running Cost/Day (Use Biomass Raw Material as Sample) | |||||

| NO. | Input | Quantity | Unit Price/Ton | Input Cost | Total Cost |

| 1 | Coconut shells | 72 Tons | 39 USD | 936 USD | $1025.345 |

| 2 | Power Consumption | 34 kw/h | 0.1425 USD/kWh | 3.845 USD | |

| 3 | Workers | 3 | 28.5 USD/Worker | 85.5 USD | |

| Income / Day (Use Biomass Raw Material as Sample) | |||||

| NO. | Output | Quantity | Unit Price/Ton | Income | Total Income |

| 1 | Charcoal 30% | 21.6 T | 700 USD | 15120 USD | $15120 |

| 2 | Wood Vinegar % | T | USD | USD | |

| 3 | Tar 5% | T | USD | USD | |

| 4 | Syngas | T | USD | USD | |

| Profit = Total Income - Total Cost = $15120 - $1025.245 = $14094.655 | |||||

Why choose Guanma Machinery Continuous Carbonizing Machine Manufacturer?

Choose Guanma Machinery for top-tier Continuous Carbonizing Machines, renowned for unmatched efficiency, reliability, and innovative solutions in carbonization technology.

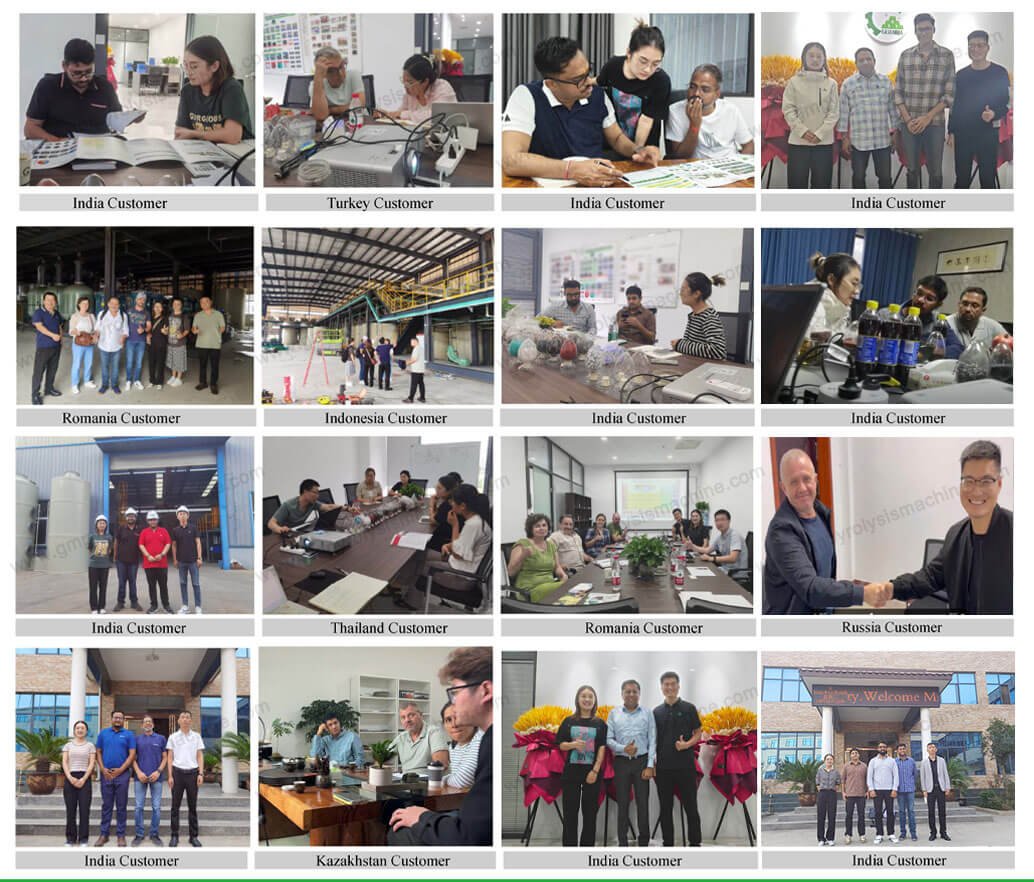

Customer Visiting

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)